Fast shipping

Expert Advice

Our laser welders are the equal of any, and the best value on the American market. Buy from us because:

Massive cost savings in production. Also uses 75% less electricity and gas.

Typically 4 to 5 times faster than TIG.

Much higher throughput and output per worker.

Full control of penetration. Penetrate fully at high speed up to 1/4″ thick.

Unskilled and lower cost workers can be used. Good welders are difficult to find.

Minimal sugaring. No rework or finishing in most cases.

Avoids spatter and sparks. Much less fire risk.

Far less shielding gas consumption due to faster welding.

No preparation required on most parts. No veeing out. You can weld straight onto galvanizing, as the laser welder has a cleaning action similar to a laser cleaner.

Quick return on investment

Laser welders use intense light as the heat source to melt materials and weld them together. The simplest explanation is that a laser welder is basically a laser cutter with a control system added to move the laser beam in a pattern that distributes the heat to melt the parts, rather than cut through them. The key parameters for laser welding are power density (how small the spot size is), how fast the beam is moved around by the mirrors, linear speed of the welding gun (laser head), and the wobble (beam movement) pattern. The weld penetration can be very deep, similar to a laser cutter, if you wish, or the parameters can be adjusted to give a small sealing weld. Laser welders are incredibly versatile and essential in any fabrication shop or factory welding parts from sheet metal.

The main types of laser welders are:

Handheld fiber lasers are continuous wave lasers, meaning steady, continuous output. Some of these have options for pulsing or cleaning.

These are pulsed, welding via powerful pulses. Usually with a boom and adjustable head with CCD video display and crosshairs, or binocular viewer. A foot pedal controls the laser firing. Our models use reliable fiber lasers, but most use xenon flash tubes, which are cheaper and old technology requiring maintenance and replacement.

These are smaller and cheaper versions of the mold repair lasers. For cost reasons they use xenon flash tubes. They must produce powerful pulses that pierce and melt reflective metals such as gold, silver, copper and platinum.

These use CNC control to move the laser in X, Y and often also Z and a fourth axis for rotation. They can be continuous wave fiber lasers or xenon arc depending on the customer’s needs. They can weld thick parts or thin sheet metal down to 0.004” or 0.1mm thickness on inconel, nickel, 316 stainless steel, etc.

Normally a fiber laser welding gun mounted on a robotic arm, or cobot.

Deliver-Eze package drop boxes wanted a quick and seamless process for assembling their column type parcelbox. By adopting laser seam welding of the steel body they could match the landed price from China while improving quality, avoiding the headaches, and enabling certification as locally made. After running a flap disk over the weld seam to remove spikes, the bodies were powder coated and came out beautifully. As a further benefit, laser welding removes coatings (galvanizing) in the weld area only, which maximizes corrosion resistance and avoids preparation. where the weld will be, removing the need to grind the galvanizing off, and preserving the corrosion resistance.

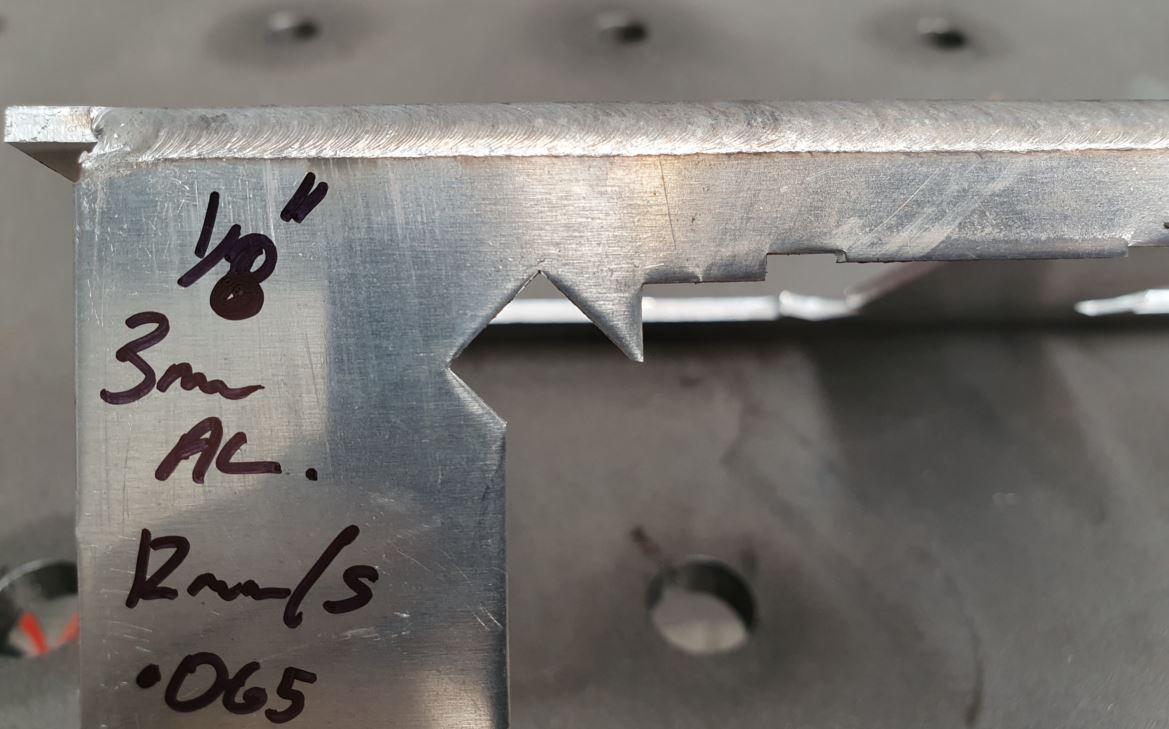

A large RV travel trailer manufacturer was arc welding aluminum side frames with unskilled labor. The welds were very lumpy and required extensive grinding at huge labor cost. They even had a guy rebuilding angle grinders full time. By switching to laser welding they were able to fusion weld the extrusions together very quickly, and keep the weld flush. No grinding required. This enabled a 70% cost reduction in side frame processing.

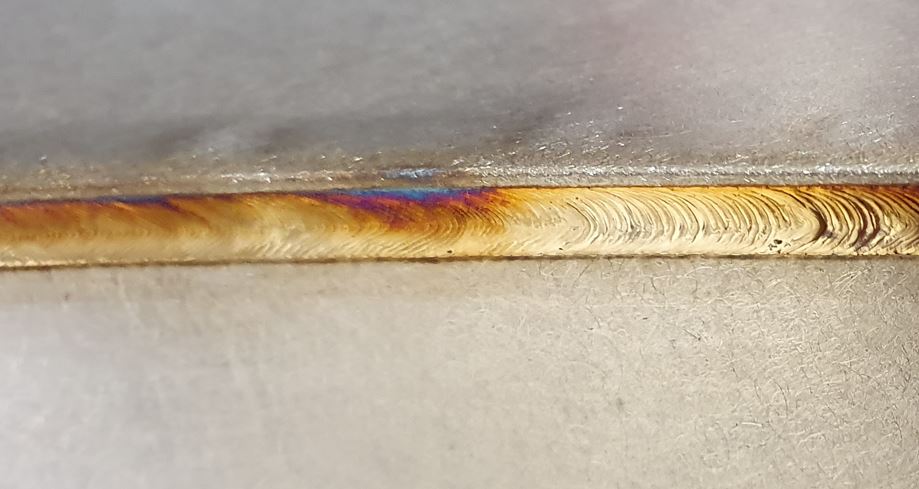

Our customer received an order for a large quantity of rectangular stainless steel tanks. They figured each one would take approximately one hour to TIG weld. We offered to trial laser welding for this project. With the parts in our demo area we arrived at a good setup after a few minutes of trialling. This used a double wobble mode as single wobble had a tendency to burn through the corners and was not as neat. Our unskilled worker welded the tank in one sixth of the time their highly skilled TIG welder would take. In addition, we used far less argon shielding gas and electricity. We fused the corners with no filler required, and far less sugaring. Another happy customer added to our books.

A customer’s welders were taking a week to TIG weld large sections of a stainless steel slide in 3mm sheet for an adventure playground. They required the weld to be strong, but NOT fully penetrate (to avoid reworking the inside of the slide). We were able to give them a consistent 70% penetration at 65% power on our G5-1500W. Our class-leading double wobble head (even IPG don’t have this feature!) gave a beautiful cosmetic weld every time, in one day or less. A massive saving for them.

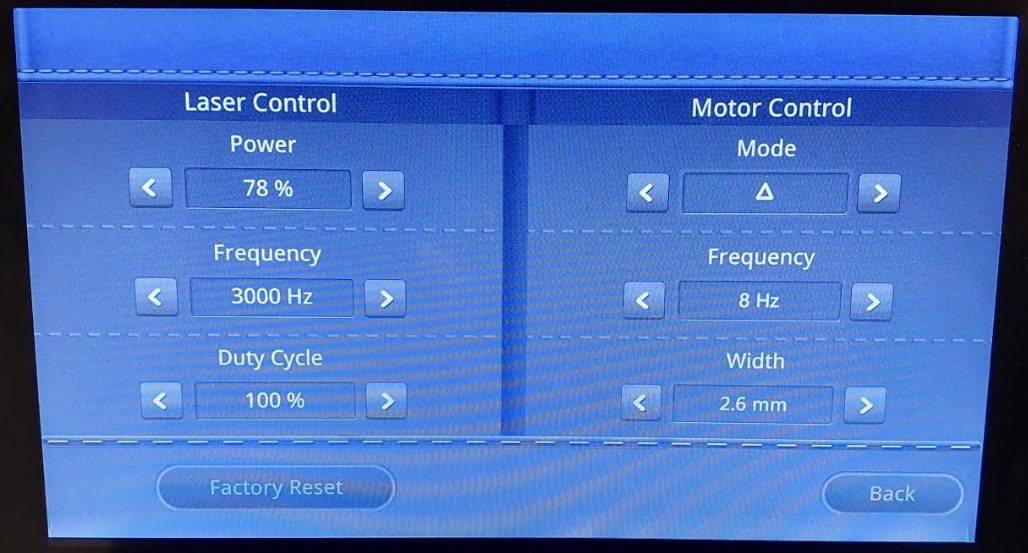

All our laser welders are continuous wave fiber laser based due to their excellent performance to cost ratio, high efficiency and high power output. Continuous wave means the laser is a continuous beam, which works well for steel and stainless steel. However our laser sources also usually have a duty cycle setting which allows you to set Pulse Width Modulation (PWM) for cleaning welds for example. We can guide you on this.

Our 100 and 200W laser cleaners are QCW switched pulsed lasers. This pulsed type has advantages for removal of paint and coatings with minimal damage to the underlying material.

Aluminum is much more difficult to weld than steel or stainless steel because:

a. In the solid state it reflects over 90% of infrared light (fibre lasers for example).

b. It has a very high thermal conductivity, sucking the heat out of the area we are trying to weld.

Fortunately, when molten it absorbs much more IR. Hence welding aluminum requires high energy density to heat a small area to the melting point, then it welds quite nicely. Note that some laser welders such as the base model IPG Lightweld and Lightweld XC have less power density than all our models (despite ours being far more affordable), so they struggle to start welding aluminum. Interestingly, our models weld aluminum at least twice as fast as the weld.com Youtube videos taken at IPG with their factory technician welding.

Aluminum and copper are difficult to weld because they are very reflective to infrared light. Same for copper, gold and silver. This is why they make excellent mirrors and reflective heat shields, but it also makes them difficult to melt with a laser. Additionally, these metals have high thermal conductivity, so they suck the heat away quickly as you heat them.

HOWEVER, our laser welders are at the top of the heap for aluminum. We weld it twice as quickly as IPG’s base models, despite IPG being far more expensive.

In the molten state aluminum and copper are less reflective, and absorb infrared. This allows us to weld aluminum using high power density. Our welders are designed to have small spot sizes, which is critical to initiate welding in aluminum, and the reason we get such excellent penetration and high weld speeds compared to others.

Stainless steel looks reflective like aluminum, but it actually absorbs much more infrared than stainless, so all laser welders should be able to weld it.

Laser welding beats TIG and MIG because it is faster, very consistent, and does not require high skill.

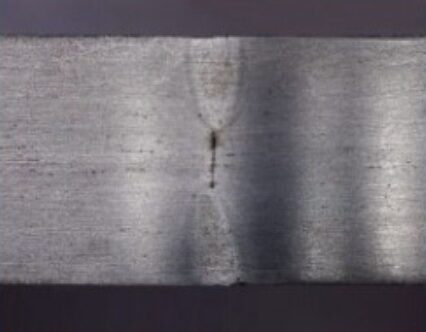

In the real world, some welds end up looking like the image above. People rush processes that take skill. In contrast, laser welding is fast and takes less skill, so the welds go out the door right first time, and usually without the need for weld dressing.

We have shown laser welding to be around five times as fast as TIG, with ¼ the heat input and distortion. It also beats MIG, with much less heat input and sugaring, no spatter, and neater welds. Deeper penetration can be achieved than TIG or MIG, but you also have the option of doing a quick sealing weld.

Yes, laser welds can be as strong as TIG or MIG and LASER WELDS ARE USALLY STRONGER. Laser welding concentrates the heat into a small area, so it welds more quickly and has a smaller heat affected zone (HAZ). The reduced heat input means the weld cools quicker and has a finer grain structure, with less degrading of the parent metal. TIG and MIG input much more heat, annealing the base metal and losing the heat treatment or cold work.

Although laser welding is most remarkable for its high welding speed, by slowing the welding speed, laser welding can give deep penetration with high weld strength in one pass. A 1500W laser welder can penetrate up to 3mm fully at high speed, for aluminum, stainless and carbon steel. However it can also do a very quick seam or sealing weld. Laser welding is superior to MIG, TIG, and stick when it comes to welding speed, heat input, distortion and stain (AKA sugaring). It provides customer-ready welds with no or minimal grinding and reworking.

Different types of lasers produce electromagnetic radiation at different frequencies (or wavelengths). These are colors of light, but they are invisible, as most of the colors fall outside the narrow range our eyes can detect. The most common wavelengths and processes are:

Usually 1064nm to 1085nm wavelength. This is invisible and called near infrared because it is not far from visible red, so this range of wavelengths is dangerous to our eyes, Great for welding steel and stainless steel, aluminum, nickel, inconel, titanium, etc. High powers available. Very good performance to cost ratio.

10,600 nm wavelength (10.6 microns, 0.011mm, or 0.00042” for reference) This is ten times as long as a fiber lasers wavelength. Invisible. Known as far infrared. They are mostly reflected by metals, so poor for welding. Good for engraving wood and organic materials.

A range of wavelengths depending on chemistry. They run from UV to visible to IR, around 450nm to 950nm. 450nm (blue and visible) looks promising for copper welding. Copper and other metals absorb shorter wavelengths (UV to blue range) more than IR. Powerful diode lasers are not commercially available yet., but I expect this technology to grow quickly in coming years.

IPG is mostly built right here in the USA (except the IPG Lightweld wire feeder which is clearly Chinese) and is one of the leaders in mainstream lasers. It was founded by Valentin Gapontsev, a Russian scientist. There are many lower volume, niche brands such as Laserline, Coherent, Laserlab, nLight, Jenoptik, Trumpf, Corona, and Jeopsys, but not at an affordable commercial level. With a totally different business model, Chinese made laser sources such as Max Photonics, Raycus and JPT benefit from low cost enabled by high volume and a strong laser industry. IPG’s laser products cost much more than the Asian units, but less than most European lasers.

Interestingly, our laser welders weld aluminum around twice as fast as IPG Lightweld and XC, based on our stopwatching of weld.com’s Youtube video which features an IPG factory technician welding 2mm aluminum. This is because our power density is higher than IPGs standard models. Only IPGs top of the line XR model matches or exceeds ours, but an XR with wire feeder and 10m cable costs close to $35,000 meaning it is more than TWICE the price of our 1500W models, It even costs double our 2kW G5-2000WC which is 33% more powerful than a 1500W unit.

If you require portability, an air cooled laser welder is best. These are lighter as there is no chiller. IPG Lightweld is the best known of this type, but our Lightwelder15 and Lightwelder20 are very similar, cheaper and have a more powerful cooling system which is refrigerated rather than IPGs heat pipe system

We recently released the first 2000W portable (air cooled) hand held laser welder, Lightwelder20. This is based on our Lightwelder architecture, looking the same as Lightwelder15 shown on the left, but with 33% more power.

Our lightwelder15 has fifteen hundred Watts of output power, with a duty cycle of 100% up to 100 degrees Fahrenheit. It weighs 120 pounds (55kg) and is 26”x12”x 24” high (650x300x620mm) so it can fit in a car or truck easily. It has class leading efficiency, requiring a 25A breaker, with peak current draw of only 17 Amps at 220V AC. However under the NEC they can use a 20A breaker if the current draw will last less than 3 hours, avoiding the 80% rule (source: se.com).

While an undergraduate I worked in the metallurgy lab of an Ordnance Factory. This involved sectioning, sanding and acid etching weld samples, along with Vickers or Brinell hardness and Charpy/Izod tests to check metallurgical properties and weld quality. Most welds were on very thick steel plates but the elements of a good weld, whether stick, TIG, MIG or laser are the same:

Adequate penetration

Correct weld size

Minimal undercutting

Metallurgical properties of the finished part.

Minimal heat heat affected zone (HAZ)

Minimal weld stain

Minimum distortion

Minimal gridding/rework required

Must be economical

LASER WELDING IS SUPERIOR FOR ALL OF THE ABOVE KEY CRITERIA.

We trialled a water cooled IPG 1500W laser welder in late 2021. The machine was fine, but we could see no benefit over our final range. Apart from its high cost, the biggest negative for this IPG unit was that the welding head only had a single wobble mode. Single wobble laser welding heads can only scan left-right. This allows basic welding, but often double wobble gives the best result. Hence our water cooled welders have our top of the line double wobble head with 6 modes. This allows allowing different trace shapes (circle, triangle and D shape for example) in addition to sigle wobble mode. These can be quickly selected, to suit different situations.

The IPG with closest performance to our 1500W welders is Lightweld XR. As of 2024 this sells for around $34,900 with a wire feeder. Our G5-1500WC is also 1500W, and costs $14,000 with our wire feeder. In summary, you could buy 5 of our systems for the cost of 2 of theirs.

We believe our laser welders are the best value on the market. We include the best and most expensive double wobble head, when most units use cheap single wobble heads. You can buy two of our machines for the cost of an upper spec IPG, and the saving from having two of our machines in your production makes the business case quite simple.

Yes, all our laser welders have a pulsed mode which allows cleaning of welds quickly and with minimal heat input.

Our 4-in-1 laser head (gun) system also allows weld seam cleaning at the push of a button, up to 8mm wide. By removing the output tube it then cleans up to 30mm (1.2 inches) wide. Changing the focus lens gives cleaning up to 80mm (3.2″) or 150mm (6″) if required. These can quickly remove rust, paint and many other items. Please note that continuous wave (lasers above 500W) are not ideal for thin sheet metal as the heat input risks distorting the panel. For thin sheet metal use one of our new, low cost pulsed laser cleaners (200W or 300W).

Laser welders with separate cleaning heads are to be avoided, as there is a high risk of head failure due to dust entry when the optics are open, AND swapping the parts can take up to an hour or so each time.

Very little maintenance is required:

Change the water monthly for water cooled models, with demineralized/deionized water.

Check the protective lens daily or when power drops at all, and replace it if you see dark spots.

Be sure to have enough argon and flow rate. The shielding gas also protects the lens.

Change the welding nozzles as they wear out from rubbing on the parts being welded.

Lasers have a very long life, rated up to 100,000 hours. This is 108 years of use at 4 hours per business day. They will save you money for many years if cared for properly. However they require a small amount of upkeep to prevent damage. Please follow these precautions:

1. Don’t damage the fiber optic cable such as cutting or kinking it (minimum recommended bend radius of 8 inches).

2. Don’t run water cooled units with low water level. Change the water every month with de-ionized or demineralized water, cheaply available at hardware stores. This avoids the possibility for algae to grow inside the chiller.

3. Allow the chiller to reach 75 degrees F (25 degrees C on the laser display) before turning the laser on.

4. Do not run the laser if humidity is above 80%. Condensation could occur in the optics, and cause damage internally. This is true for all laser welders.

5. If you notice a power drop or the laser is not welding correctly, stop. In a dust free environment (not windy for example) remove the very front lens (protective, sacrificial lens) and check for any dark spots. If found, replace the lens, taking care to cover the opening with tape so dust cannot enter the head. Only touch the new lens on the outside or not at all, and certainly not on the flat sides. Spangle galvanized steel will spark and smoke more than other types, and requires more frequent lens changes.

6. Do not weld with the head perpendicular (90 degrees) to the weld surface, which could cause the laser to be reflected back inside the unit. Best welding is achieved with the gun around 45 to 60 degrees to the surface being welded, so you should never need to orient the head at 90 degrees. 90 degrees is also reflecting laser energy back at the user, so should never be done for safety reasons. See our safety section.

7. Be sure to have adequate gas supply, and typically run it at 32 CFH (15 liters per minute).

Laser-welder is the only seller we know of that actually uses lasers in our production! Most other companies are generalists and machinery sellers, with far less idea of how to set up or weld with them, or the practical aspects. Our Australian division is the largest seller of laser welders in Australia, and their relationships with customers and continuous welding trials for new customers leaves us with a large knowledge base and expertise. We can separate marketing hype from fact, based on our laser welder manufacturing experience, and put forward the best solution for customers.

Click to Know More!

All laser welders and cutters are defined as Class IV lasers, meaning their output is dangerous because it can start fires and burn skin and eyes. See our laser safety page for information on the safety requirements.

However a couple of Chinese laser sources have electrical safety issues which should not really occur, and are designed out of our laser welders. I am talking specifically about Raycus and a lesser known brand, where they designed the connector/s for the water cooling circuit to sit directly above the mains voltage connector.

As a former General Motors and Siemens engineer for safety related systems I have to question how “switched on” those two laser source suppliers are. As you may imagine, we don’t use them.

For our own Generation 5 (G5) laser welders, we designed the breaker section according to UL50, and use UL listed switches and breakers, along with many UR and UL components internally.

LASER stands for Light Amplification by Stimulation of Emitted Radiation. Historically they used a chamber with an excited gas, which resonates the light in a chamber, typically a glass tube of gas such as CO2. This electromagnetic radiation or light bounces back and forth, then it bursts out past a partial mirror when the energy reaches a certain level. It’s not of much practical importance to us, but this output is notable because the waves all have the same frequency and phase, known as a coherent electromagnetic field.

A fiber laser is a laser that uses the differing refractive indices of multi-layered glass fiber, to efficiently transmit and pump the laser from one or more diodes. They have become popular in recent years, but were actually demonstrated 60 years ago, in 1963 by Elias Snitzer.

The inner glass fiber is coated in one or more layers of glass with different refractive indices. Due to Bragg gratings and a partially reflective section, the outer layers in the fiber then aid the reflection/capture and emission of light at a certain frequency, in a resonant manner. The fiber also allows a closed system for transmission of the laser power from the source to the welding or cleaning head, for targeting at the work piece.

A laser welding machine (simply referred to as a laser welder) uses focused infrared light to heat materials to the melting point, so they can fuse or weld together. This can be done by fusion, AKA autogenous welding, where no filler wire is added. If the gap between the materials being welded is more than about 0.2mm, filler wire can be used to fill the gap and/or create a larger fillet.

Note that a laser welder with a slow-moving beam is actually called a laser cutter. Hence the welding head on a laser welder must move the focused beam quickly, so the heat is distributed optimally for melting, and not quite cutting through the part.

The control system for the welding head controls the laser, when the trigger button is depressed on the welding gun. Moveable mirror/s are precisely computer controlled so the laser traces a defined path. In simple laser welders like IPG Lightweld, and most on the market, this is done in one dimension, scanning left and right. This is known as single wobble. However for many situations two dimensional scanning gives the best welds, and this system is known as double wobble. This allows the welding gun or head to trace any shape from a pin point up to a 5mm circle, oval, hourglass, triangle, etc. Double wobble also allows some pre and post heating, which can reduce cracking in 6000 series aluminum and other crack sensitive materials.

Flexible delivery of the laser power is a key benefit. Without fiber, laser welding would be very difficult. Fiber lasers also feature high efficiency with high power output and reliability. In fact our air cooled laser welder has an efficiency of 42%, which is the equal of any industrial laser, while our water cooled laser source is considerably more efficient than the common Raycus sources.

All the fiber lasers we sell emit wavelengths around 1075nm (1064 to 1085nm), but fiber lasers are not limited to 1075nm.

China is the largest producer of lasers and laser welders. It has a very active laser industry, and their low cost environment allows similar products to be made for a much lower cost, as for most electrical and electronic products. Interestingly, many European brands are also made in China, such as the Bystronic (Swiss) laser welder I saw in May 2023. However Amada (Japanese) is swimming against the tide, sourcing IPG Lightweld as their 2023 laser welder, which is sold for an eye-watering price…

Argon is the best shielding gas for all metals and is what we recommend. Nitrogen can be used for mild steel and most grades of stainless steel if you prefer.

Yes. Our lasers have a cutting mode, and the kit comes with a nozzle with a small hole. When used at 80 PSI (5.5Bar) the small hole and high pressure blows the dross away to give a fairly clean cut. If this feature is important, please discuss and we can set you up with a head for even higher pressures, which gives a very clean cut edge. assists this. FYI, for welding the gas pressure is much less, around 30 PSI (2 Bar) or 15 liters per minute.

Around 1kg, but the weight does not matter. Unlike TIG and MIG, laser welders MUST be held in contact with the workpiece. This makes welding easy, and the weight of the gun only helps you maintain contact. If the head is lifted from the workpiece the safety earth circuit (red clamp) interlock will disable the laser until it sees electrical continuity or contact again. This is a safety feature in hand held laser welders so you do not inadvertently fire a laser pistol around the room.