Can you laser weld Stainless Steel?

Yes, you can laser weld stainless steel with any of our laser welders. Stainless is actually the easiest metal to laser weld.

Yes, you can laser weld stainless steel with any of our laser welders. Stainless is actually the easiest metal to laser weld.

Stainless steel has a lower thermal conductivity than steel or aluminum. This means it requires less power to form and maintain a molten pool.

Its absorption of infrared heat is similar to steel, and far higher than aluminium. Once again this reduces the heat input (power) required.

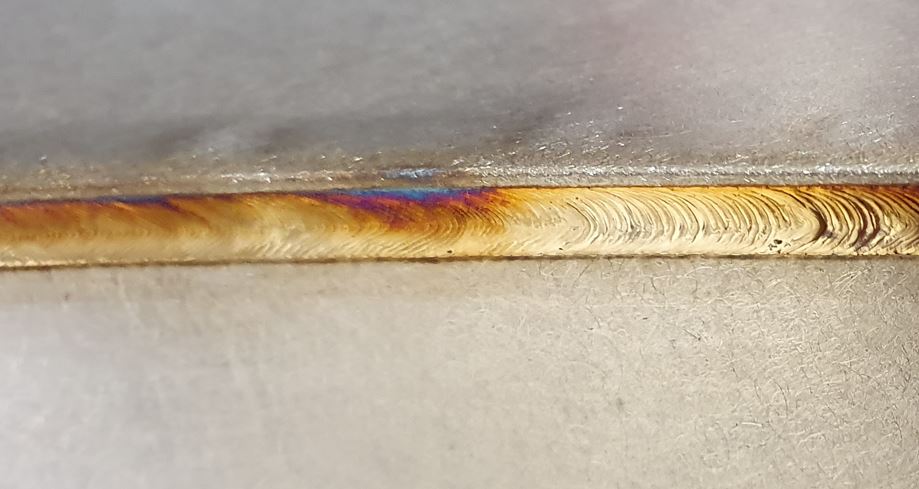

It is also very rare to get pops or craters in stainless, so making a beautiful weld is easy and repeatable.

Laser welding is better than MIG or TIG. It is an amazing process for welding stainless steel. Laser welding solves all the problems experienced when TIG or MIG welding stainless:

Laser welding is usually stronger than MIG or TIG. A customer who makes high end swimming pools for penthouse apartments etc. was concerned about strength (for very obvious reasons!). Hence they recently tested our Lightwelder 20 on 1/8″ and 4mm stainless steel, making samples for testing. They also TIG welded comparison samples. These had a larger weld fillet due to more filler material, and the welding college personnel were sure the TIG welded sample would be stronger. Despite this, the laser welded samples were stronger than the TIG welded samples. The reason for this is quite simple. TIG is far slower, with a wider, higher heat input. Stainless sheet gets a lot of its strength from rolling (cold working), but the heat of TIG welding basically anneals the material back to its soft state. Laser welding’s much lower heat input retains most of the original strength.

The maximum thickness stainless steel a hand held laser welder can weld is 1/4″ or 6mm. Our 2kW laser welders can weld up to 4 gauge (6mm) stainless steel with full penetration in one pass. This requires slower welding speed and good fit up.

If you need to weld thicker than 4mm, a 3kW laser welder can weld 1/4″ thickness with high speed, or even thicker by slowing down. Check out our newly released G5-3000WC. It can punch straigth through 1/4″ steel plate even with a brief tack weld!

The best shielding gas for laser welding stainless steel is argon. However Nitrogen can also be used with great results. In the end, the decision of which gas to use is a commercial one. Nitrogen is recommended if you have a nitrogen generator or buy it cheaply. If you do a lot of TIG or aluminum welding you will likely choose to keep using argon shielding gas.

Quality of the gas is also worth considering. If you are welding critical components or have any concerns such as soot or contamination, try a higher quality gas supplier.